MANUFACTURERS AND SUPPLIERS OF QUALITY MARINE EQUIPMENT

|

| |

|

ITW Chockfast Orange® |

|

|

| |

|

|

|

|

| |

|

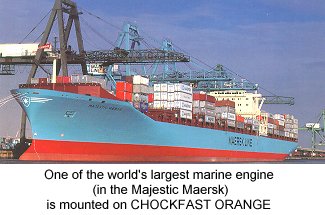

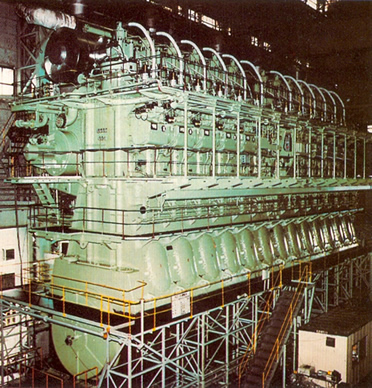

Philadelphia Resins CHOCKFAST ORANGE is an epoxy based pourable compound that cures at normal temperatures to become an extremely tough and durable solid. CHOCKFAST was specifically developed for chocking marine main propulsion and auxiliary machinery and since its introduction in 1963 has earned the approval of the major classification societies worldwide.

The widely acknowledged superiority of CHOCKFAST chocks over those of steel or cast iron has led to their adoption throughout the world by ship owners and shipbuilders. Many thousands of ships with engines up to 70,320hp have logged millions of hours at sea with CHOCKFAST chocks.

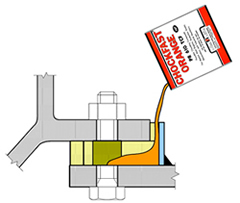

Since the machining of foundations is not required and all machining and hand fitting of chocks is eliminated, the cost and time required for machinery installation are dramatically reduced.

Because of the full contact intimate fit of CHOCKFAST chocks to the mounting surfaces, fretting of the chocks and loosening of hold-down bolts are eliminated. Thus the original alignment may be retained indefinitely.

While the physical properties of CHOCKFAST ensure alignment, the compressive modulus is substantially less than that of steel, providing a mounting with decided advantages under shock loading and often much smoother and quieter operation. |

|

|

* Approved by Classification Societies worldwide.

* Greatly reduced time and cost of machinery chocking.

* Eliminates machining and hand fitting of metal chocks.

* Proven superior to fitted steel chocks and alignment retention.

* Eliminates loosening of holding down bolts. |

|

Conveniently pourable, two-component, structural epoxy "chock" that replaces tediously fitted steel chocks (or steel shims) assuring intimate contact with machined or un-machined equipment bedplates.

Virtually 100% effective bearing underneath supported equipment. |

|

Guideline for Marine Designers

Technical Bulletin 692

|

Chockfast Orange can be used under diesel engines, petrol engines, gearboxes, generators, compressors, pumps, bearing blocks, crane rails and numerous other applications. |

Chockfast Orange Properties

Technical Bulletin 659 |

Chockfast Orange

Industrial Bulletin 1032 |

| Main engine chocking |

|

|

|

Chockfast materials and techniques have been developed to permit precision chocking work on site with minimal time required. Directed by an approved Applicator Engineer, the work can be undertaken by whatever work force is available.

As approved applicators C.E.& A Co. offer design checking, load calculation, pouring and pouring supervision services within Australia.

|

| |

|

|

| |

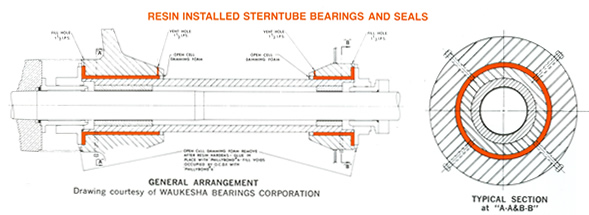

| Chockfast Orange can also be used in the installation of sterntube and stern bearing carriers. |

Installing a vessel's sterntube bearing or 'A' bracket (Skeg) bearing by using the Chockfast Orange method eliminates the costly need to 'line-bore' for final bearing alignment and simplifies what can be a lengthy procedure. The bearing sleeves or complete inner sterntube can be checked for alignment before final chocking or, if required, the propeller shaft can be installed to guarantee fit prior to chocking. |

|

|

|

Installation Guideline for Sterntube Installation

Industrial Bulletin 632 |

2 Sterntubes ready for installation,

On the right is the S/Steel inner tube with bearing.

Centre is the Aluminium constructional tube.

Left - an assembly together showing the jacking bolts and fairing cone. |

| |

| Because of our knowledge of the material C.E.& A Co. were contracted to secure the supply of CHOCKFAST to the Australian ANZAC Frigate project for the installation of the sterntubes and to provide training to the shipyard. The installation was the first time a sterntube system was installed using CHOCKFAST on a combat vessel. |

| |

| The use of Chockfast Orange is not limited to marine applications, it can be used under an extensive range of land based equipment as well, at CE&A we have chocked a light aircraft engine test bed, oxygen generator base and power station generator as well as an old diesel/electric locomotive front bogie mount. |

|

|

|

|

BOC Whyalla Oxygen Generator.

After the old, oil impregnated and cracked concrete was removed Chockfast Red was used to build up

the foundation.

The generator base plate was then position and aligned, Chockfast Orange was poured as the final chock. |

|

| |

Turbine driven power generator.

In an attempt to reduce vibration in a power generation unit, Epirez 280S with added Aggregate and Chockfast Orange were poured under an existing installation. Whilst not 100% successful it did reduce the vibration. |

|

|

|

|

| This was actually quite a difficult job as access at the back of the generator was limited. |

|

Pouring chute |

Not pretty but we got it in! |

|

|

|

|

|

| The frame dam for the Epirez 280S. |

Frame in position under the generator. |

Pouring the Epirez 280S. |

Epirez 280S pour complete. |

| At the front of the generator two 900mm square x 75 deep frames were positioned and sealed to pour a foundation layer of Epirez 280S. Once cured a strip of damming foam was pushed in place to form the dam for the Chockfast Orange. Preparation has a great deal to do with the success of any pour, in this case extra time was take to ensure the dam was correct as if a leak occurred we would have had no chance of sealing it. Our care paid off - no leaks! |

|

|

|

|

|

| Mixing the Epirez 280S and Aggregate. |

|

| Each 900mm square Chockfast Orange chock was poured in one go, internal design of the dam meant the Chockfast Orange flowed down one side and up the other, pushing the air out as it went. |

Pouring the Chockfast Orange,

again using a pouring chute |

Successful pour. |

|

|

|

| |

|

|

During its operational time with the Commonwealth Railways the NSU suffered a derailment, damaging the frame above the mount. The NSU has now being restored by the Pichi Richi Rail Preservation Society, however they were having trouble keeping the bogie mount secured in place. C.E.& A. Co were approached as to the viability of pouring Chockfast Orange between the uneven frame and the bogie mount. We volunteered our time and successfully poured the Chockfast Orange.

Note the pouring and vent tubes in the picture at left. |

| The NSU diesel/electric locomotive whist under restoration. |

The NSU diesel/electric locomotive front bogie mount. |

|

|

| |

| C.E.& A. Co. are suppliers of Chockfast Orange and Epirez products to the Australian Defence Force Submarine and AWD projects as well as many other Marine and Industrial applications. |

|

|

| |

|

|

| |

Chockfast and Epirez Products:

Chockfast Orange

Chockfast Red

Phillybond Products

Concrete Repair Epoxies

Structural Adhesives

Epoxy Grouts

Floor Coatings |

|

Also available from C.E.& A. Co. |

- - Propeller Shaft and Rudder Bearings - -

- - Propeller Shafts and Sterntubes - -

- - Rudder Carrier Bearings and Rudder Trunks - -

- - Water and Oil Lubricated Shaft Seals - -

- - Deck Machinery - -

- - Polyflex - Engine Mounts and Couplings - -

- - Spurs - Rope, Net and Weed Cutter - -

- - Arctic Steel - Stainless Steel Water Strainers - -

- -

Vickers Marine Oils - - |

| |

Home Page |

| For further information, or to purchase Chockfast or Epirez products please contact us. |

| |

|

|

|

| |

| |

|

5 Schenker Drive, Royal Park.

South Australia. 5014 |

Ph: 08 8240 0777 |

Int. Ph: +618 8240 0777 |

E-mail: ceaco@ceaco.com.au |

|

|

| |

|