MANUFACTURERS AND SUPPLIERS OF QUALITY MARINE EQUIPMENT |

|

PolyFlex Engine Mounts and Couplings |

|||||||||||||||||||

C.E.& A. Co. have been a supplier of Poly Flex equipment for over 30 years, and as such have a good knowledge of the their products. We have supplied Poly Flex Mounts and Couplings to all types of vessels from Naval Patrol Boats to yachts that have competed many times in the great Sydney-Hobart Yacht Race. Talk to us, so we can supply them to you. |

||||||||||||||||||||

|

||||||||||||||||||||

| Both engine and drive line vibration have been an issue in the marine industry for a long time. At Poly Flex their goal is to improve this dramatically even to the point were it becomes non existent. They have developed a range of high quality engine and machinery mounts and flexible drive couplings, tailored to meet the demands of today's requirements. | ||||||||||||||||||||

| Reduced Vibration - Increased Protection | ||||||||||||||||||||

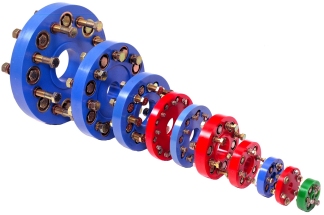

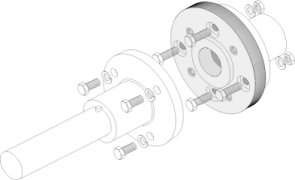

| ENGINE COUPLINGS | ||||||||||||||||||||

Long-lasting Poly Flex flexible disc transmission couplings provide a damper between the gearbox and propeller shaft to isolate torsional vibration from the engine and gearbox. It also reduces the shock of forward and reverse gear changes. The result - the level of engine and transmission noise transmitted into the hull structure is reduced. Their couplings work in conjunction with the engine mounts by providing the softest element in the shaft assembly to improve performance. All metal components are plated in SA5 Cobalt Zinc for maximum corrosion resistance and durability. The moulded components are manufactured from a special range of engineering heat cured polymer alloys that are highly resistant to salt-water, oil, diesel, petrol and most solvents. All their components are proudly designed, engineered and manufactured by Poly Flex. |

||||||||||||||||||||

|

||||||||||||||||||||

Minimise

the damage An added bonus of the Poly Flex Coupling is the electrical isolation it provides between the engine and shaft, helping to reduce electrolysis. |

||||||||||||||||||||

| To specify the correct Poly Flex Coupling for you application we will need the following information: |  |

|||||||||||||||||||

| Make and Model of the Gearbox. Rated horsepower of the engine. |

||||||||||||||||||||

If we can not identify the coupling required from the gearbox make we will need the additional information: |

||||||||||||||||||||

Number and Diameter of gearbox bolt holes. |

||||||||||||||||||||

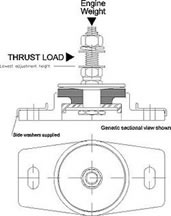

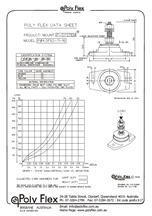

| ENGINE MOUNTS | ||||||||||||||||||||

Poly Flex mounting systems are designed as true marine propulsion engine mounts with sufficient vertical deflection to obtain proven vibration isolation. They have controlled minimum thrust and lateral deflection under propulsion load and inertia due to sea conditions. They are also designed to be directly interchangeable with those supplied with engines from the major engine manufacturers and have a fail-safe that in the event of a capsize the engine will not break away from it's bearers. Moulded components are manufactured from a special range of engineering heat cured polymer alloys. Poly Flex mounts are also suited to the mining, defence, industrial,commercial, agricultural and automotive industries. They also manufacture mounts for instrumentation.

|

||||||||||||||||||||

| Also available from CE&A Co. |

|

|||||||||||||||||||

| Arctic Stainless Steel Water Strainers | ||||||||||||||||||||

|

||||||||||||||||||||

| Tufnol Marine Bearing Materials | ||||||||||||||||||||

|

||||||||||||||||||||

|

||||||||||||||||||||